it all Began With a Couple of Dreamers

Actually, artists and dreamers. That describes Les Rose and Bill Motre, Romo’s founders, perfectly. Just shy of a decade after World War II, Les and Bill combined their last names to form “Romo,” and began their pursuit of the American dream. They had a passion for bringing art to life in places that others considered mundane. They created eye-catching logos, decals, and advertisements for car dealerships, retail stores, and businesses all over Green Bay, Wisconsin. All of the art was drawn freehand, and carefully crafted with screens, ink, and quality materials. Each piece was lovingly created and treated as a real work of art.

Les and Bill created all kinds of artwork, some of them big and some small. They drew everything one layer at a time, one layer for each color, and used a large camera to blow the art up to the proper size. When a job called for multiple parts on a single sheet, each photo of the artwork was hand cut, stepped and repeated on a grid. Die lines were invented to make sure that everything lined up perfectly. Getting the proper registration and perfectly cut lines required meticulous attention to detail. The process took a long time, often several weeks from start to finish. Creating the artwork required intense collaboration with clients, and because everything was so manual, it was difficult to do business over long distances.

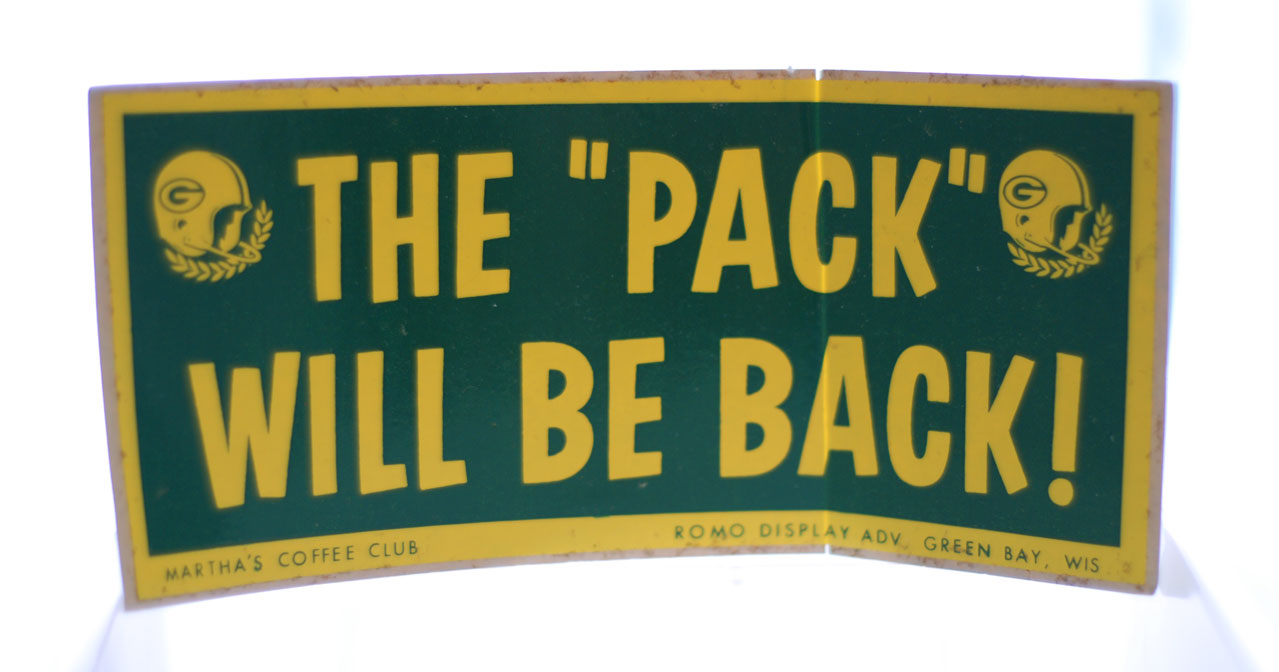

Developing One of the World’s Most Recognized Logos

Green Bay is home to one of the greatest sports franchises in history, the Green Bay Packers. And it just so happens that Romo used to be located about one block away from the team’s headquarters. When Romo had its offices at the corner of Washington and Doty streets in downtown Green Bay, Les and Bill would run into members of the Packers organization all the time. They developed a good relationship with Gerald “Dad” Braisher, the team trainer and equipment manager. Dad used wooden placards to label each player’s locker, and Les hand lettered each and every one of those placards for him. Romo was also printing promotional bumper stickers for the Packers.

In the early 60’s, Vince Lombardi wanted a logo for the side of the Packers helmet. Dad worked with a St. Norbert’s University intern named John Gordon to create a mock up of a “G” in the shape of a football. Then he handed the idea over to Les, and from there Romo developed the art for the Packer “G” known around the world today. The logo first appeared as a “bumper sticker” on the side of the Packer helmets.

The Changing of the Guard

In the 70’s, the printing industry started to focus more on the printing process. The Press Gazette, Green Bay’s daily newspaper, took an interest in Romo because they wanted to expand into the outdoor advertising market. Romo’s large format printing capabilities would allow the Press Gazette to offer billboards and signage as part of their expanding product portfolio. The Press Gazette owned Romo throughout the 70’s, but when Gannett purchased the Press Gazette later that decade, they weren’t interested in continued development of the outdoor market, so they put Romo up for sale.

Fred Darling and Turner Harshaw, both durable graphics industry veterans who learned the ropes selling unique substrates, saw an opportunity to build upon Romo’s great reputation in the industry. Fred and Turner acquired Romo in 1983, and they brought a sales and customer service focus that grew Romo substantially throughout the 80’s and 90’s. The Darling family took on sole ownership of Romo in the mid 90’s when Turner retired.

The Strategic Fork in the Road

Around that same time, as Romo transitioned its ownership structure, the entire printing industry changed it’s foundational structure. Artwork went digital, which had immediate and far-reaching effects on how business was done. Digital artwork not only improved workflow, but also made the process of creating and editing art transportable. You didn’t have to be located close to your customer anymore, and gradually graphics producers started aligning around markets instead of geographic territories.

That fundamental change presented some real strategic challenges for Romo, which up until that time had been serving several niches including Point of Purchase (POP), architectural and Original Equipment Manufacturer (OEM) graphics. As each niche market became more sophisticated, it became difficult to run such a wide variety of business under one roof. For example, because Romo was offering some leading-edge inventory management services to OEM’s, Romo had the opportunity to supply owner’s manuals and other non-durable graphics on a just-in-time basis. To do that well required different machines, different raw materials, and different expertise. Romo had come to a fork in the road.

The leadership team, after serious deliberation, realized that producing durable graphics was in the company’s DNA. That was their passion. From that point forward, the company’s focus became the graphic, not the equipment used to produce it. Gradually, Romo shifted from an “inside out” to an “outside in” approach. The goal was, and is, to find ways to design and engineer a durable graphic that delivers value from the client’s perspective, then figure out how to produce it.

That change in mindset resulted in innovative ideas that out-stripped the capabilities of the company at the time. Instead of relying on outside sources for innovation, Romo developed an internal R&D group and made additional investments in training and equipment. The company’s first internally developed innovation, an in-mold graphic, rolled off the line in the late 90’s. The objective was to help customers eliminate the need to manually apply graphics. The initial version showed promise but required fine-tuning. Eventually, the in-mold graphic innovation led to a geographic expansion of the company. Today Romo sells that product throughout the United States and around the globe.

Discovery Happens Here

Fred Darling decided to retire in 2007. Fred’s son, Jonathan, had joined the company in the mid 90’s. Jonathan succeeded Fred as President of Romo Durable Graphics, allowing the company to remain a privately held, family business. Today, Romo maintains the values Fred instilled in the business while continuing its pursuit of creating “durable graphics that make a difference,” one application at a time. That customer-centric discovery process has led to many creative innovations, from the way parts are designed, ordered, inventoried and applied, to performance in the field.