History of Romo Durable Graphics #4

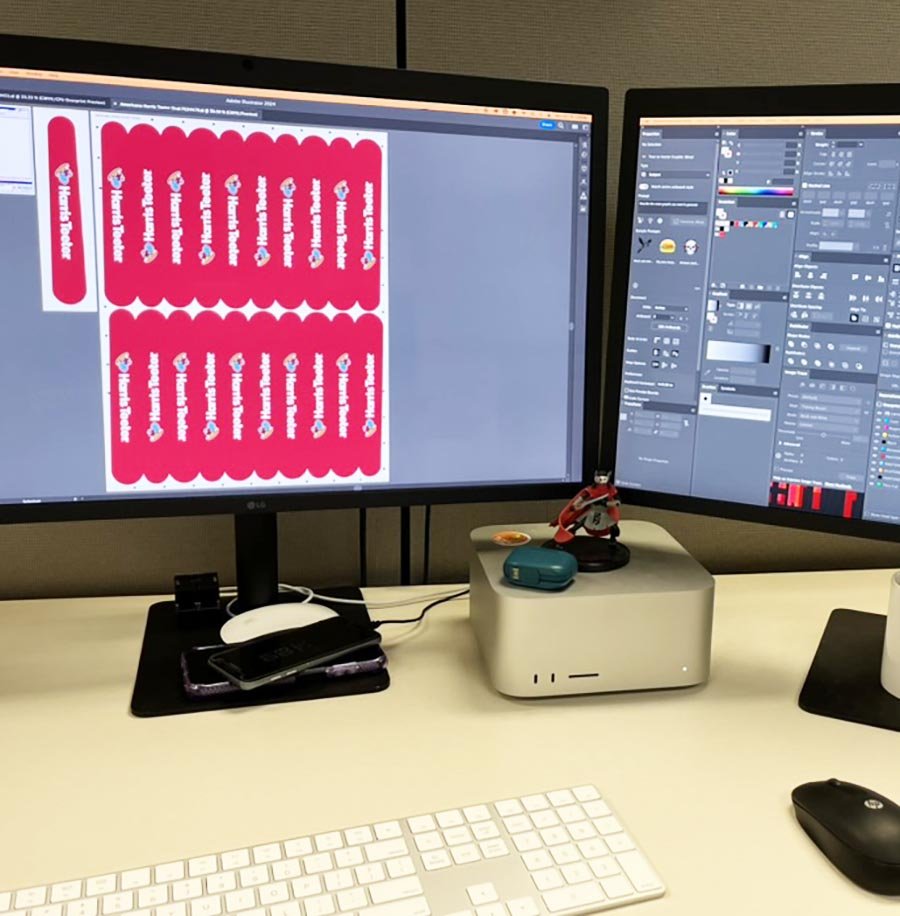

As Romo transitioned its ownership structure, the entire printing industry changed its foundational structure. Artwork went digital, which had immediate and far-reaching effects on how business was done. Digital artwork not only improved workflow, but also made the process of creating and editing art transportable. You didn’t have to be located close to your customer anymore, and gradually graphics producers started aligning around markets instead of geographic territories.

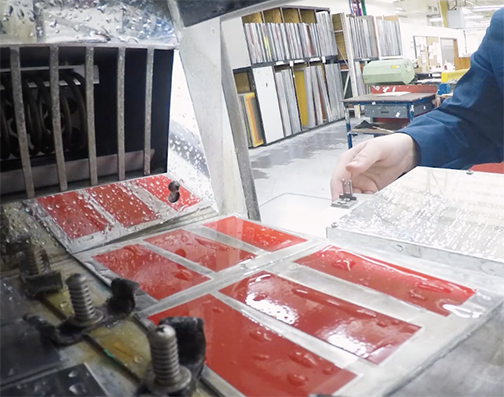

The leadership team, after serious deliberation, realized that producing durable graphics was in the company’s DNA. That was their passion. From that point forward, the company’s focus became the graphic, not the equipment used to produce it. Gradually, Romo shifted from an “inside out” to an “outside in” approach. The goal was, and is, to find ways to design and engineer a durable graphic that delivers value from the client’s perspective, then figure out how to produce it.

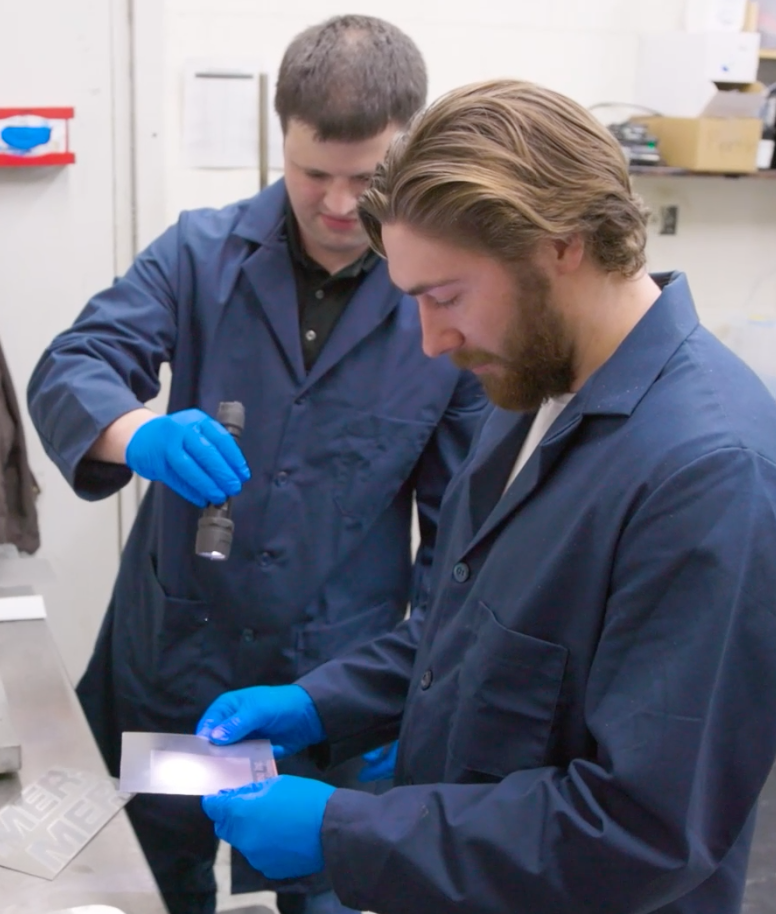

That change in mindset resulted in innovative ideas that out-stripped the capabilities of the company at the time. Instead of relying on outside sources for innovation, Romo developed an internal R&D group and made additional investments in training and equipment. The company’s first internally developed innovation, an in-mold graphic, rolled off the line in the late 90’s. The objective was to help customers eliminate the need to manually apply graphics. Today Romo sells that product throughout the United States and around the globe.